OECD 301 Ready Biodegradation Test

Concept

As the first tier of tests in OECD standard methods for biodegradebility evaluation, OECD 301A-F have been popularly used in both scientific studies and industries. While methods A-F do share some similarities, they still possess a lot of differences regarding the system setup, analytical principles, and applicabilities.

A material is considered Readily Biodegradable if 60% (for OECD 301 B-D and F) or 70% (for OECD301 A and E) of the degradation reached within a 10 day window and within 28 days total. The 10 day window is defined as beginning when 10% of the degradation is reached and ends after 10 days from this point (but before 28 full days of the test).

Please refer to the page "Test Method Overview" for more concepts or overview about OECD 301.

Brief overview of OECD 301A-F methods

OECD 301A DOC die-away

The OECD 301A DOC die-away test focuses on the removal of dissolved organic carbon (DOC) during the biodegradation process. As the ultimate biodegradation of a chemical results in the cleavage of the whole structure of the molecular for the formation of CO2 and H2O, this process consumes the organic carbon originally present in the test substance. Therefore, the direct measurement of DOC in the incubated solution can well reflect the biodegradation of the target compound.

To ensure the applicability of this method, the carbon content of the test substance should be known and the substance should be soluble so that the DOC can be quantified. It should not be easily adsorbed by any materials present in the incubation system such as the inoculum, reactor walls, mixers, and the aeration apparatus.

In addition, since aeration is performed for this method, the test substance should not be volatile.

For more details about this method, please refer to the related OECD official site and document.

danger

The DOC die-away methods can easily result in falsely high degradation percentages due to the adsorption of the test substance by materials present in the incubation system such as the inoculum, reactor walls, mixers, and the aeration apparatus. DOC can also be absorbed by the filters while sampling.

Avoid using this type of tests unless you are sure your samples will not have such issues, or appropriate control tests are done simultaneously.

OECD 301B CO2 evolution

The OECD 301B CO2 evolution method focuses on the quantification of the CO2 that is generated during the biodegradation process. As the chemical decomposition process primarily result in the formation of CO2 and H2O, the measurement of generated CO2 can well reflect the biodegradation of the test compounds. With the measured and the theoretical CO2 amount, one can easily calculate the degradation percentages over a specified incubation time.

Different from 301A, the aeration of the working solution requires the use of CO2 free air, which can be easily obtained by using a few NaOH washing bottles to remove all the CO2 present in the air. After that, CO2 free air can be send to aerate the working solution.

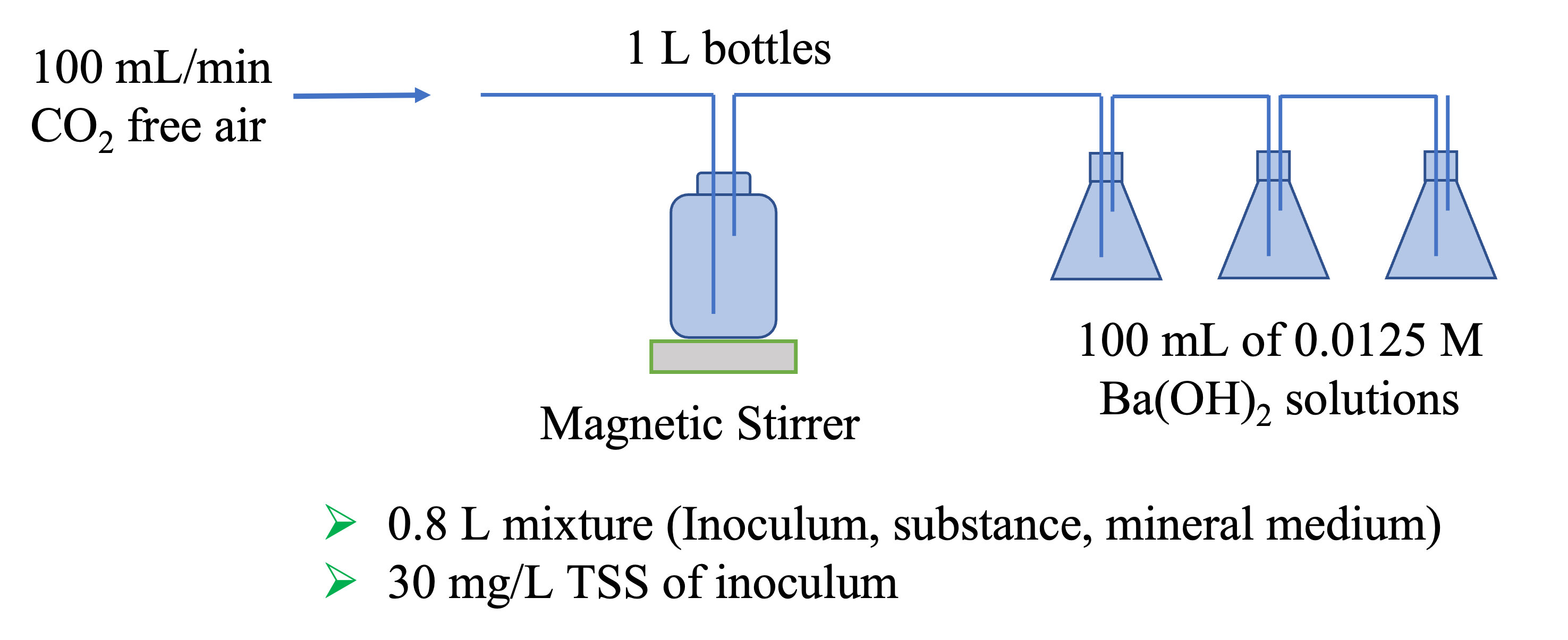

During the aeration, CO2 may be generated as a result of test substance biodegradation. Such CO2 can be easily stripped off the working solution. To capture it, three absorption bottles are usually used containing known amount of Ba(OH)2 to convert CO2 into BaCO3 solid. An afterwards acid-base titration using HCl as the titrant can determine the residual amount of Ba(OH)2, which can well reflect the amount of CO2 generated during the biodegradation.

Figure 1. OECD 301B experimental setup

Figure 2. OECD 301B setup scheme

This method is appropriate for highly soluble, poorly soluble and/or absorbing materials. However, since aeration is performed throughout the incubation process, the test substance should not be volatile. Common materials tested by OECD 301B include lubricants, grease, oil, fuels, surfactants, and personal care products.

For more details about this method, please refer to the related OECD official site and document.

OECD 301C (modified MITI test (I))

The OECD 301C method is a modified Ministry of International Trade and Industry, Japan (MITI) aerobic biodegradation test. Similar to the closed bottle test (301D), it measures the DO consumption to calculate the BOD of the test compounds, based on which the biodegradation percentage can be calculated.

It usually uses automatic electrolytic BOD meters or respirometers equipped with cups containing CO2 absorbent to quantify the DO consumption during incubation.

This method is capable of testing samples that are poorly soluble, volatile, and/or adsorbing. While testing volatile compounds, however, the headspace in the reactor should be minimized to ensure that all the compounds are well present in the working solution in contact with the inoculum.

This method is similar to 301F, with the major difference in the inoculum. A mixture of at least 10 sources of inoculum collected from places like surface water, seawater, and soil, were precultured for at least one month with synthetic sewage wastewater. Then the resulted activated sludge is used for 301C.

For more details about this method, please refer to the related OECD official site and document.

OECD 301D closed bottle

The OECD 301D closed bottle test measures the DO consumption during biodegradation and the degradation percentage is calculated as the ratio of DO consumption to the theoretical DO consumption. This process also involves the calculation of BOD (biochemical oxygen demand).

Different from the BOD test for water quality evaluation (e.g., EPA Method 405.1), where the unit of BOD is mg DO/L, the unit of BOD for the biodegradability test is mg DO/mg substance (even though it can be converted to mg DO/L).

This method is capable of testing samples that are poorly soluble, volatile, and/or adsorbing. While testing poorly soluble compounds, however, the shaking of the reactors during incubation might be helpful to improve the dissolution.

The formula of the test substance and its purity may be known so that the ThOD can be calculated. If the ThOD cannot be obtained, the chemical oxygen demand (COD) can be experimentally determined and used as a less satisfactory alternative. However, this may lead to falsely high degradation percentages as COD could sometimes be smaller than ThOD if the test substance is not completely oxidized in the COD test.

Figure 3. Standard OECD 301D closed bottle method for biodegradability test.

For more details about this method, please refer to the related OECD official site and document.

important

Due to its simplicity and high applicability, 301D has been one of the major methods we use at Aropha for ready biodegradation test.

OECD 301E modified 301A (DOC die-away)

The method OECD 301E shares the principles with OECD 301A as both of them focus on the DOC removal during the incubation process, but the former employs a relatively lower concentration of microorganisms. Details can be found in upper sections.

In order to employ this method, the carbon content of the test substance should be known and the substance should be soluble so that the DOC can be quantified. It should not be easily adsorbed by any materials present in the incubation system such as the inoculum, reactor walls, mixers, and the aeration apparatus.

In addition, since aeration is performed for this method, the test substance should not be volatile.

For more details about this method, please refer to the related OECD official site and document.

danger

The DOC die-away methods can easily result in falsely high degradation percentages due to the adsorption of the test substance by materials present in the incubation system such as the inoculum, reactor walls, mixers, and the aeration apparatus. DOC can also be adsorbed by the filters while sampling.

Avoid using this type of tests unless you are sure your samples will not have such issues, or appropriate control tests are done simultaneously.

OECD 301F closed respirometer

The OECD 301F closed respirometer method determines the biodegradability of a material by measuring the DO consumption during the biodegradation process in a period of 28 days in a closed bottle setup. The degradation percentage is calculated as the ratio of DO consumption to the theoretical oxygen demand (ThOD). It is similar to the 301C, mainly differing in the inoculum employed.

Different from the OECD 301D closed bottle test, this method employs much higher dosages of the test substances and inoculum and therefore requires headspace in the reactors to provide adequate oxygen for the microorganisms.

The oxygen consumption is determined by measuring the quantity of oxygen (produced electrolytically) required to compensate the consumed one to maintain a constant gas volume/pressure in the respirometer flask, or from the change in the volume or pressure in the flask without compensating the consumed oxygen. The evolved CO2 is absorbed by sodium hydroxide solution present in a tube in the flask.

Similar to OECD 301D method, the formula of the test substance and its purity may be known to calculate the ThOD. If the ThOD cannot be obtained, the chemical oxygen demand (COD) may be experimentally determined and used as a less satisfactory alternative. However, this may lead to falsely high degradation percentages as COD could sometimes be smaller than ThOD if the test substance is not completely oxidized in the COD test.

This method is capable of testing samples that are highly soluble, poorly soluble, insoluble, volatile, and/or adsorbing. It has therefore been often used for materials that the OECD 301B and OECD 301D methods cannot handle (e.g., insoluble and volatile).

For more details about this method, please refer to the related OECD official site and document.

Applicabilities of OECD 301A-F

Table 1. Applicability of test methods 301A-F for compounds with different properties

| Test | Analytical method | Poorly soluble | Volatile | Adsorbing |

|---|---|---|---|---|

| 301A (DOC die-away) | Dissolved organic carbon | - | - | +/- |

| 301B (CO2 evolution) | CO2 generation | + | - | + |

| 301C (Modified MITI test (I)) | Oxygen consumption | + | +/- | + |

| 301D (Closed bottle) | Dissolved oxygen (BOD) | +/- | + | + |

| 301E (Modified 301A) | Dissolved organic carbon | - | - | +/- |

| 301F (Manometric respirometry) | Oxygen consumption | + | +/- | + |

For more details about the individual methods A-F, please refer to the related OECD official site and document.

Why do we choose OECD 301B, 301D, and 301F?

Compared to other methods, OECD 301B, D, and F have the top levels of simplicity and applicability.

301B can handle most materials except the volatile ones.

OECD 301D has a very simple system setup, and can be used for a wide range of compounds that are highly soluble, poorly soluble, volatile, and adsorbing.

OECD 301F is appropriate for highly soluble, poorly soluble, absorbing, and volatile (or not volatile)) materials. It has been very widely used to test lubricants, grease, oil, fuels, surfactants, and personal care products.

important

The automation-assisted sampling, data analysis, and Aropha Console have largely improved the stability, repeatability, and cost-efficiency.